| Engineering And Technology | ||

In-House engineering facilities include:

Most common works we undertake on engine components:

Fully Modified Cylinder Heads:

|

||

| Machine Shop | ||

We have the facilities to design and fabricate just about any part from wishbone to flywheel. Our in-house CNC machine shop is able to cater for the demands of maintaining and developing unique cars and engines. Allied with Laser scanning and processing technology the machine shop is able to create exact replications of parts from solid. |

||

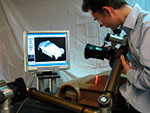

| Laser Scanning | ||

Components that need to be reproduced are scanned using our 3D laser scanning equipment. |

||

| CAD Design | ||

CAD models are generated from the scan data. This allows components to be manufactured using a variety of methods. Examples are CNC machining, investment casting, sand casting, body panel fixtures, pressings and rapid prototypes. |

||

| Body Panel Fixtures | ||

Whole cars are scanned, and the data is archived for use in the future. |

||

| 3 and 4 Axis CNC Milling | ||

Our machine shop can produce a variety of complex parts; examples of these include suspension, engine and chassis components. We specialize in one off parts, but also produce in volume when required. |

||

| Pattern Design and Manufacture for Sand Casting | ||

Casting patterns are designed from the component CAD model. They are machined in-house using our CNC equipment. We then use various foundries to produce castings in aluminium, cast iron, and magnesium. This picture illustrates a gearbox bellhousing manufactures for Kit-Cars and Special Vehicles – Rear Wheel Drive. Mounts Ford Rocket or Type 9 Gearbox to Renault F7R / F4R and 5 GT Turbo type engine. |

||

| Tool Design and Manufacture for Investment Casting | ||

Aluminium tools are designed and manufactured in-house. These are used for investment casting. |

||